- Arduino robotic arm driver#

- Arduino robotic arm full#

- Arduino robotic arm code#

- Arduino robotic arm Bluetooth#

Arduino robotic arm Bluetooth#

The Arduino UNO, on its side, does not have Bluetooth Low Energy communication, so we used an HC-05 module for this purpose. The Raspberry Pi 3 plays a fundamental role: it runs handle inputs from the human arms, translates it in servos’ positions and then send the new position to the robotic arm. We used to control Robot Arm made in Italy The bottom row will show NA indicating no data is available.Simple Arduino UNO board. The top row will still show the joystick signals, however, the connection status will show an X. The following image shows the LCD status with a failed connection between the controller and robot arm. The bottom row shows the servo angles and the status of the claw (open or close). The top row shows the direction of the joystick signals, and the state of the connection between the controller and robot arm. The following image shows the LCD status during normal operation. Currently, this is only used to inform the operator and does not impact system operation. This command allows the controller to know whether it has a live connection with the arm. Arm feedbackĪfter processing arm movements, the arm transmits its status back to the controller.

Arduino robotic arm code#

The current code commands the servos using microseconds instead of angles, giving servos higher definition movements. All movements are processed before the actual movement is given. If the movement is valid, the movement delta is added or subtracted from the current servo time.

Arduino robotic arm full#

Some servos (like the shoulder rotation) can rotate to their full range, whereas others have restricted movement (like the end-effector claw). Arm movementįor each movement received, an error check ensures the command keeps the servo within its operational range. The delta indicates how much a servo should move, with a higher number indicating more movement. When a packet is received and buffered, an error check ensures the value is between expected ranges, and converts the byte into a movement delta. The robot arm continually seeks new data. This provides a more fluid control environment due to shorter latency between human input and arm movement. It is more important to stream current commands than to receive individual command confirmations. The controller only waits 1 millisecond before sending the next transmission. Utilizing the RadioHead library and UDP protocol approach, the control data is transmitted to the base. The analog signals are converted into a byte, and packaged into an array for transmission. Simple noise processing ensures only actual joystick movements are processed, and not potentiometer noise or joystick misalignment. The controller detects changes in the joystick positions. You will also need to supply a 6 volt power input to the PCA9685 with at least 2 amps of current.

Arduino robotic arm driver#

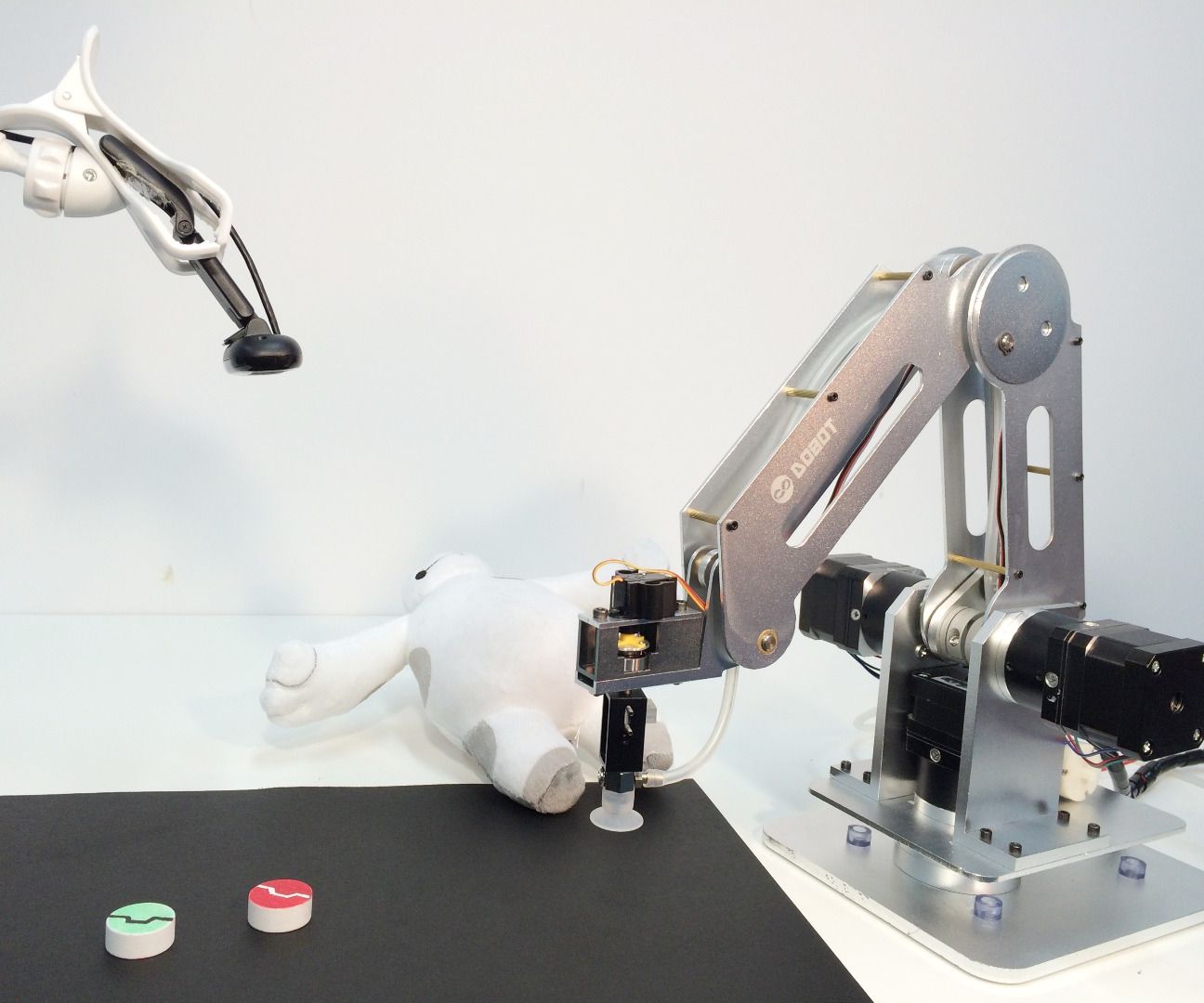

The code in this repository assumes you are also using an I2C servo controller, hence the use of the Adafruit PCA9685 PWM Servo Driver Library included in the platformio.ini. So I replaced the SainSmart servo shield for the PCA9685. The PCA9685 I2C PWM driver provided that, allowing its dedicated controller to exclusively send PWM signals to the servos. If I wanted to use the nRF24L01, I needed to find another solution. The cause of the issue was related to inconsistent PWM signals being send to the servos due to the nRF24L01 interrupting the system. When trying to use the Sainsmart exclusive servo shield, the servos became very jittery. A nNRF24L01 2.4 Ghz radio transceiver performs communication functions with the controller. Arm joints include the shoulder rotation, shoulder elevation, elbow elevation, wrist elevation, wrist rotation, and end-effector open/close movement. The robot arm uses 6 servos to control arm movement. A NRF24 2.4 Ghz radio transceiver handles communication functions with the robot base. A 16x2 LCD shows relevant information, including joystick inputs, connection status, and arm status. The controller uses two joysticks for collecting human inputs. The robot arm uses an Arduino Mega2560 and PCA9685 board, where the controller uses a Arduino Uno and shield. The system comprises two arduino controlled components: the robot arm and the controller. This is important for this project because it is using two Arduinos. PlatformIO handles complex Arduino projects better than native Arduino IDE.

If you want to duplicate the same development environment, I recommend you use VSCode with PlatformIO. You can read my post about the project here. This repository contains the code needed to remotely control the 5 DoF robot arm that I built here.

0 kommentar(er)

0 kommentar(er)